Since 1965, Air Systems has been developing process air equipment solutions for a wide range of industrial applications in Michigan and throughout the US. Through the years we have developed solid partnerships with key industry suppliers to offer the industry’s best equipment. While we are an all-inclusive manufacturer’s representative, we also serve our customers as a comprehensive solution source with complete metal fabrication capabilities.

The Air Systems team began offering metal fabrication services to our customers in 2003. As a full service supplier, we needed a streamlined way to serve custom products and manufacturing needs for ancillary equipment in addition to selling process air equipment. We saw the opportunity to develop a strategic partnership with the newly formed Industrial Metal Fabricators (IMF) to broaden our offerings while improving lead times, costs, and efficiency.

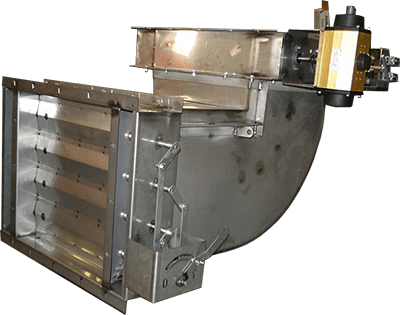

Working with IMF, Air Systems develops custom structural and sheet metal fabricated products to meet the specific needs of our customers. Our team is able to create integrated system solutions by combining the experienced expertise of the Air Systems sales and design team with the highly skilled workforce at IMF.

Our portfolio of metal fabrication products, integrated systems, and turn-key projects represents a wide range of IMF services, including:

- Custom products and fabrication

- In-house design and engineering

- 2-D and 3-D drawing capability

- In-house laser cutting

- Custom paint or powder coat finish

IMF maintains an ample 25,000 square foot facility for manufacturing and assembly, including a high bay assembly area with a 30 foot under hook height. The facility has three 5-ton overhead gantry cranes, two of which are used in the high bay area. Air Systems is able to provide full metal fabrication capabilities through IMF’s extensive array of equipment. Except for the Amada laser, purchased in 2011, all IMF’s equipment is less than three years old. The list includes:

- Amada FOM2 3015NT 4000 watt Laser, 5’ x 10’ sheet size with maximum thicknesses of ⅞” Mild steel, ½” Stainless Steel, ⅜” Aluminum

- Ermaksan Speed Bend Pro, Press Brake, 195 Ton x 12’ Bed, CNC controlled

- 5’ WDM Power Roll

- HYD-MECH #S-20A Horizontal Band Saw w/ Auto-Feed

- Exclusive Miller Invision 352 MIG welders

- Exclusive Miller Syncrowave 350LX TIG welders

Air Systems’ partnership with IMF has allowed them to effectively serve our customers in the industrial and automotive supply chain with high volume metal fabrication needs. At the same time, our team has the experience and flexibility to also serve smaller volumes and prototype needs. Applications and products we have served include:

- Heater Boxes

- Dip or Pump Tanks – large and small

- Fan and Duct Silencers

- Electrical Control Rooms (insulated or non-insulated)

- Outdoor Environmental Sheds

- Mezzanines

- Handrails

- Platforms

- Custom Structural Steel

- Water Test Booth

- Fan Inlet Boxes

- Turning Vanes

- Parts Washers

- Evaporative Humidifiers

- Carbon Filter Houses

- Custom Framed or Frameless Safety Glass Enclosures

- Equipment Safety Guarding

Air Systems is uniquely positioned to provide metal fabrication services to complement our dependable line of process air equipment solutions. Through our dedication to continually developing new products and ways to serve the industrial process air market, we confidently welcome any metal fabrication project challenge. Contact us to discuss your needs.