Mist Eliminators

Designed to Address Specific Mist Elimination Needs

Air Systems represents Munters, a global leader in mist elimination technology. Every application is unique and with Munters technology and Air Systems product experience, together, we provide the correct total integrated solution for our customers. Our mist eliminator technology offers the following advantages:

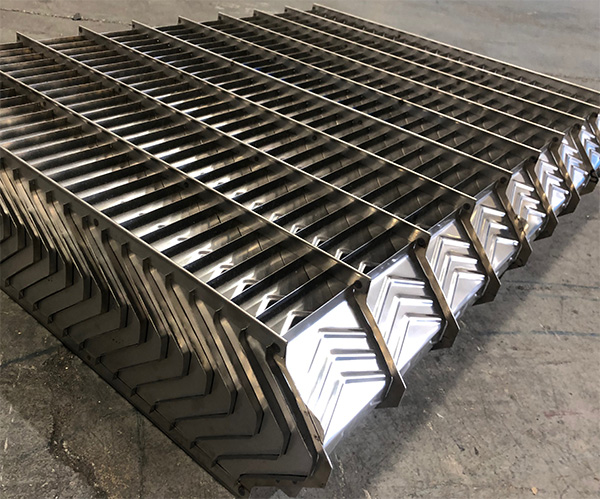

- Comprehensive eliminator designs in various materials of construction are available

- Eliminators are available in profile packs or cassette modules and custom sizes are the norm

- Eliminators available for horizontal or vertical air flows

- Quick turnaround on proposals and approval drawings

- Quick delivery (standard or custom design)

Air Systems has over 30 years’ experience providing mist eliminators in a wide range of applications from paint booth back sections to potato chip de-watering.

Applications

- Parts Washer Exhaust

- Carrier Cleaner Recirculating Systems

- Evaporative Media, Spray or Fog Humidification Systems

- Power Plant Stack/Tower Exhaust

- Wet Spray Booth Scrubber

- Pulp and Paper Processing Plants

- Food Processing Plants

- Rendering Plants

- Building Ventilation Air Intake

- Help Me Choose

- FAQ

- Manufacturers

- Resources

Due to the many variables in mist elimination, please call our office at (248) 549-1105 and speak with one of our product specialist to determine your mist eliminator solution.

QUESTION: Is there a difference between horizontal and vertical mist eliminator designs?

ANSWER: Yes, designs are not universal. There are different blade designs for each.

QUESTION: What materials are available for horizontal airflow applications?

ANSWER: PVC, Polypropylene, Aluminum or Stainless Steel

QUESTION: What materials are available for vertical airflow applications?

ANSWER: Polypropylene, FRP, Stainless Steel

QUESTION: Can you provide blades in a module or pack?

ANSWER: Yes, we only ship in profile packs or framed modules – we do not sell individual blades.

QUESTION: What is the maximum temperature rating for the blades?

ANSWER: 130 degrees F – 430 degrees F for non-metallic, 500 degrees F for aluminum and 800 degrees F for stainless steel

QUESTION: What do I need to provide for a proposal?

ANSWER: Available size, airflow (CFM), installation arrangement (vert or horiz), airstream temperature, entering droplet size and required leaving droplet size or efficiency and preferred material of construction (if known)

QUESTION: Do you provide mist eliminator vessels?

ANSWER: Yes, we can provide for vertical or horizontal airflows and design for in-duct or flange mounted installations

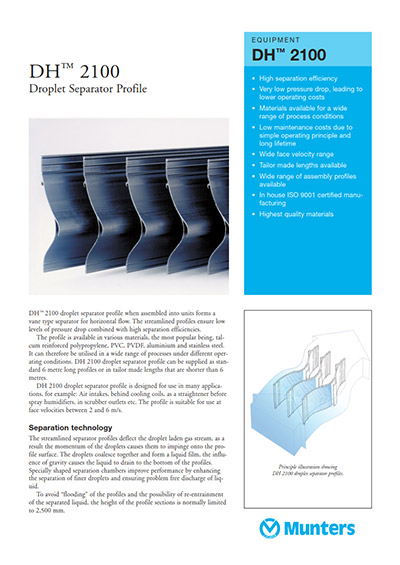

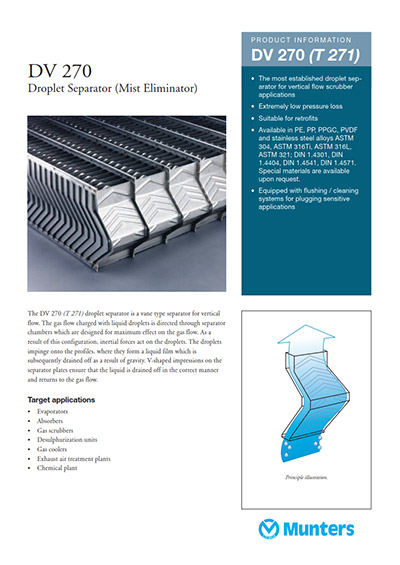

Munters

Munters is a global leader in mist elimination technology and combined with Air Systems 30 years of product and field experience, we have a proven track record of providing custom engineered solutions for our customers.