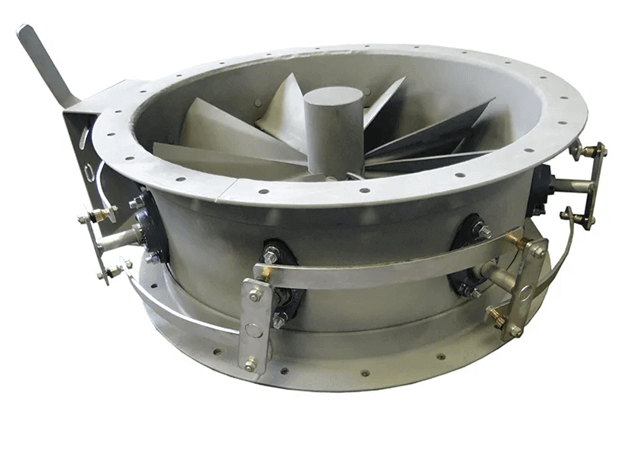

Variable inlet vane (VIV) dampers modulate the flow/pressure ratio of a blower from the inlet side. These dampers are used when applications require fan volume control (4 to 1 turndown). By controlling the rotation of the air entering the fan, the VIV can reduce fan pressure without impacting the speed of the fan.

The variable inlet vane can be opened or closed at varying degrees, depending on the needs of the application. Partially closed VIV blades pre-spin the air, directing it into the wheel in the same direction of the rotation. This effectively reduces the capacity, static pressure, and the brake horsepower (BHP).

Air Systems offers manual and automatic variable inlet vane dampers for fan inlet and volume control applications. Our variable inlet vane dampers offer an expected turn down ratio of four to one on volume while maintaining peak static pressure.

Air Systems Variable Inlet Vane Damper Advantages:

- Imperial and metric sizes available

- Quick drawings and delivery – expedited delivery available

- Custom coatings available – enamel, epoxy or powder

- Automatic operation by electric, pneumatic or hydraulic actuator (2-position or modulating available)

- Designed and built to bolt directly to a specific fan manufacturer’s inlet flange or duct work.

Air Systems offers a variety of construction material options including galvanized, aluminized, galvanneal, or stainless steel. The type of airstream and the temperature will determine the best material for the application.

With Air Systems, you can rely on the performance of your variable inlet vane damper because it will be designed and built to meet the specification needs of your application. Orders typically ship within 3-5 weeks, depending on actuator lead time.

With over 20 years of experience, the Air Systems team is highly skilled in the development of successful variable inlet vane applications. Our experienced sales staff will assist in selecting the proper damper design and material selection during the proposal process. Contact us to discuss your application.