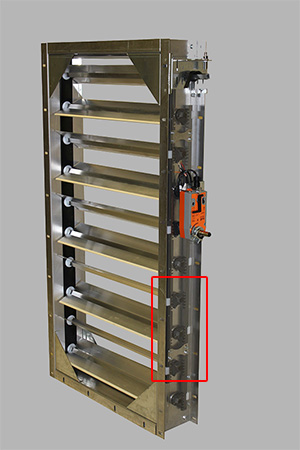

Air Systems developed and patented a unique gear drive damper design that is not only cost efficient in operation, but also offers long term dependability. This unique design relies on rack and gear drive principles, which significantly reduces the operating torque and component wear.

A key feature of the Air Systems patented gear drive damper design is the elimination of the expensive motor/actuator, which is typically required to power a damper. Our design uses special materials of construction for each component to reduce coefficient of friction. This means a much less expensive actuator can be used, greatly reducing the price of this damper as compared to conventional dampers.

Our maintenance-free gear drive damper offers the most cost-effective installed automatic damper solution. Other distinct advantages of our patented design include:

- Ultra-low torque design allows the use of fewer actuators, reducing cost

- Gear drive damper design can be used for new or retrofit installations

- “Weldless Design” – uses bolted construction requiring no welding or touch up paint

- Completely customizable

Air Systems gear drive damper meets or exceeds typical delivery requirements. Our design allows quick turnaround of drawings and our team builds every order in house for total control of quality and delivery.

Air Systems gear drive dampers have been in service over 15 years, with over 1,000 installed an no replacements to date. Contact us to learn more.